Web Menu

Product Search

Exit Menu

News

How to install V-3 CLAMP-IN METAL VALVES

2024.07.19

2024.07.19

Industry news

Industry news

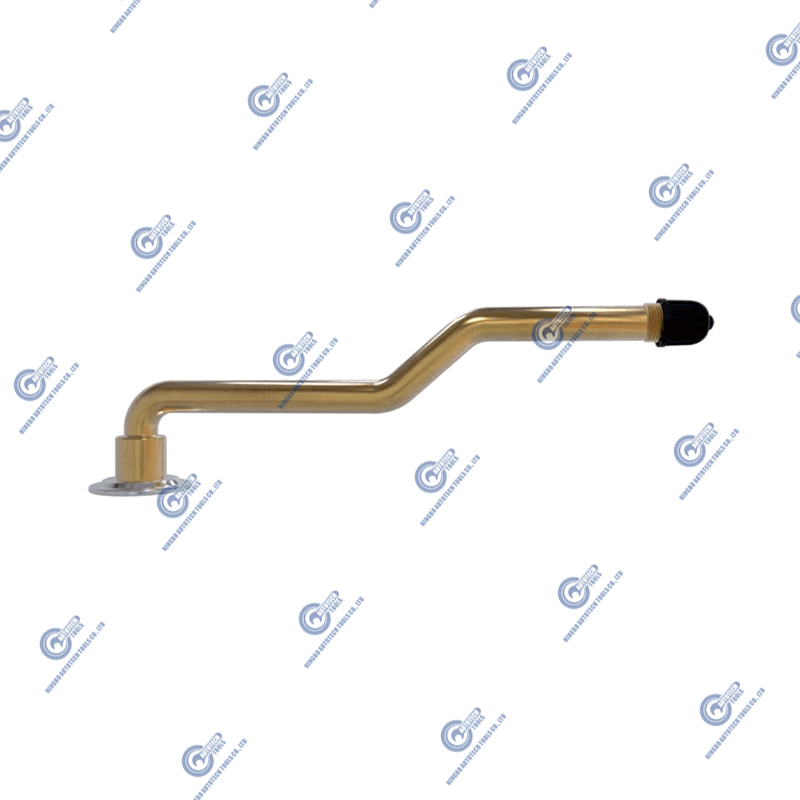

In the field of commercial vehicles and passenger cars, tire valves are an important part of vehicle safe driving. The quality and stability of their installation are directly related to the performance of tires and the overall safety of vehicles. V-3 CLAMP-IN METAL VALVES, as a metal clamping valve designed specifically for tires, has been widely welcomed in the market due to its advantages such as easy installation and good sealing.

1. Preparation

Before installing V-3 CLAMP-IN METAL VALVES, you need to make adequate preparations.

Tool preparation: Although the installation of V-3 CLAMP-IN METAL VALVES is relatively simple, you still need to prepare some basic tools, such as wrenches, screwdrivers, valve core wrenches, etc., to ensure that all tools are clean, undamaged, and in good working condition.

Check tires and rims: Before installing new valves, carefully check the status of tires and rims. Make sure that the tires are not damaged, leaking, or abnormally worn, and that the holes in the rims are clean, free of rust or debris.

Choose the right valve: Choose the right V-3 CLAMP-IN METAL VALVES according to the specifications of the tire and rim, and make sure that the valve matches the hole diameter of the tire rim to ensure a good sealing effect.

2. Installation steps

Remove the old valve: Use a valve core wrench or similar tool to gently rotate and pull out the old tire valve. Be careful not to use too much force to avoid damaging the rim or tire. If the old valve is difficult to pull out, try to apply some lubricant around the valve to help it pull out smoothly.

Clean the rim hole: Use a clean cloth or paper towel to carefully clean the rim hole to ensure that there are no impurities, oil or rust in the hole to ensure that the new valve can fit tightly.

Install the new valve: Align the clamping part of the V-3 CLAMP-IN METAL VALVES with the rim hole and gently push it in. During the push-in process, pay attention to keep the valve aligned with the hole to avoid tilting or twisting. When the bottom of the valve contacts the rim, use a wrench to gently rotate the valve so that its clamping part is firmly stuck on the rim.

Check the tightness: After installation, carefully check the tightness of the valve. You can check by inflating the tire and observing whether there is any leakage around the valve. If leakage is found, recheck the installation of the valve and make sure it is properly clamped on the rim.

Adjust the air pressure: According to the recommended air pressure value of the vehicle manufacturer, the pressure gauge inflates the tire to the appropriate air pressure range. Be careful not to use excessive force during the inflation process to avoid damaging the tire or valve.

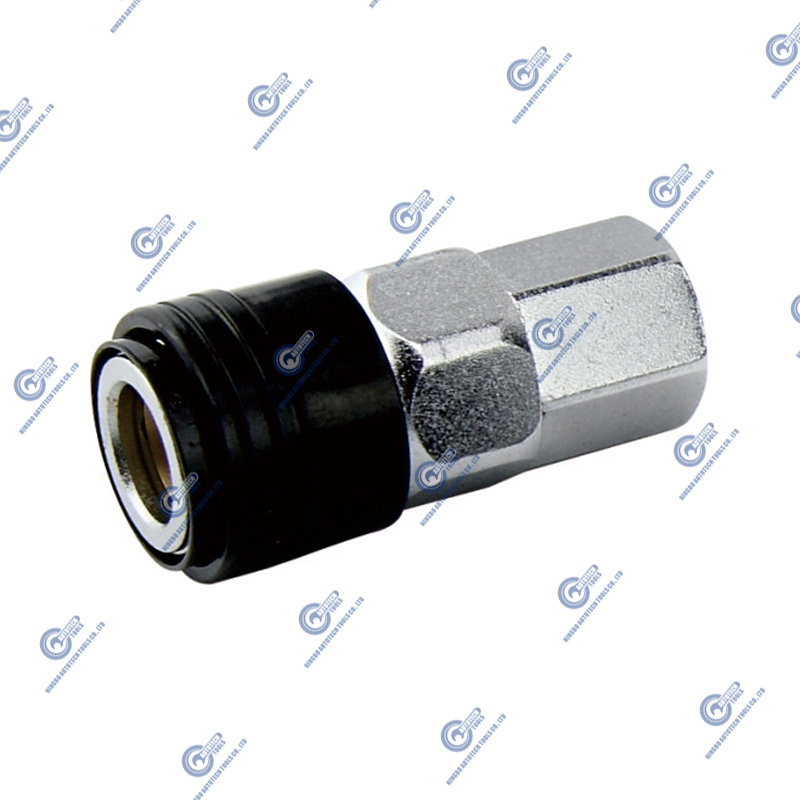

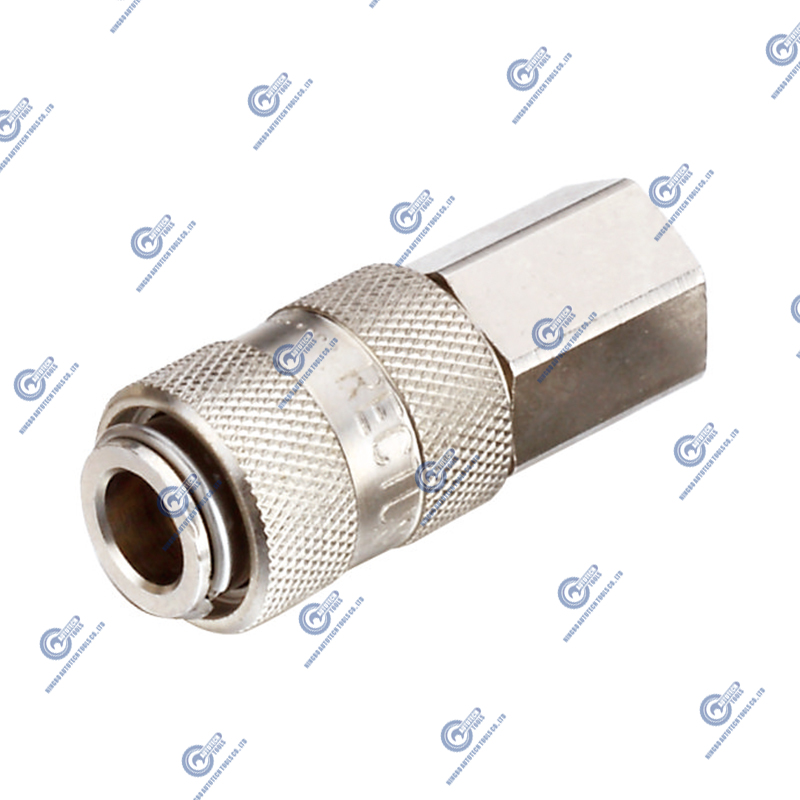

Recommended Products

Ningbo Autotech Tools Co.,Ltd was founded in 2014 as a professional manufacturer of tire valves, tire repair tools & air quick couplings.

Product links

Contact Us

-

Address:No.16 Gaoqiang Road, Jiangnan Industrial Zone, Gaoqiao Town, Yinzhou District, Ningbo, China. 315175

-

Tel:+86-0574-89073063

-

E-mail:jimmy@autotechtool.com