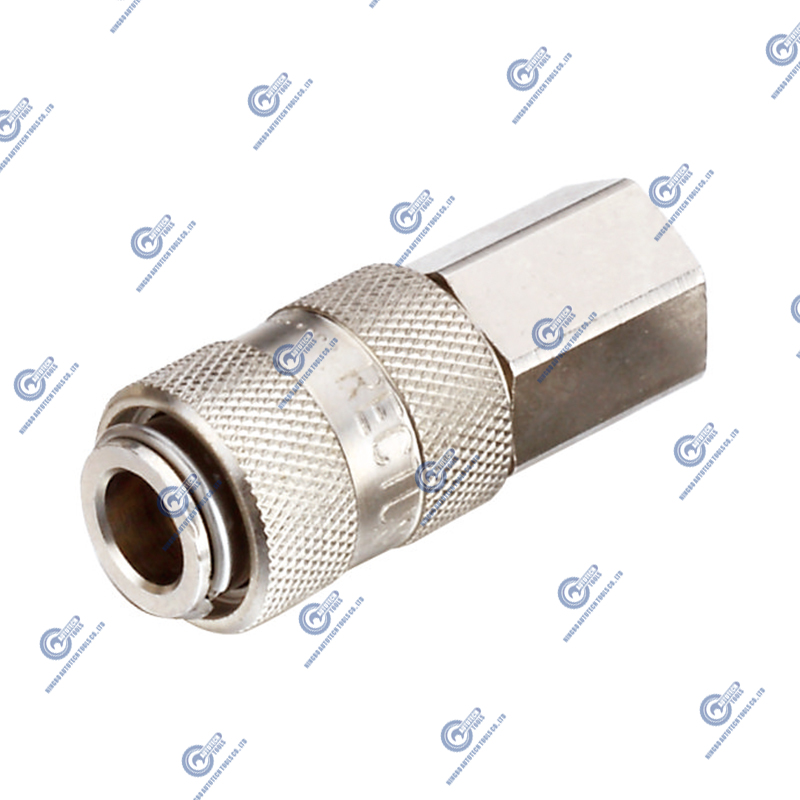

Characteristics of carbon steel air couplers and plugs

2024.09.19

2024.09.19

Industry news

Industry news

Carbon steel air couplers and plugs excel in specific applications, especially in medium and high voltage systems with significant pressure resistance.

The biggest advantages of carbon steel are its high strength and good pressure resistance. Carbon steel is able to withstand higher operating pressures than brass and aluminum and is commonly used in medium and high pressure pneumatic systems above 1000 PSI. The pressure resistance of carbon steel couplers mainly comes from its high yield strength and tensile strength, which allows it to maintain structural integrity under high pressure for a long time and is not prone to problems such as deformation and rupture.

Tensile Strength: The tensile strength of carbon steel typically ranges from 400 to 800 MPa, depending on the carbon content and steel type. This allows carbon steel couplers to handle the high-pressure gas flows that occur repeatedly in pneumatic systems.

Fatigue resistance: Carbon steel performs better than many other materials in long-term high-pressure operations, especially in operations with multiple connections and disconnections, and is less prone to fatigue failure due to pressure fluctuations or repeated mechanical stress.

Carbon steel has good machinability and can be made into complex coupler and plug structures through conventional machining methods such as turning, milling, and drilling. This feature enables carbon steel gas couplers to maintain high manufacturing accuracy and have a greater advantage in production costs. Compared with stainless steel, carbon steel has lower material costs and processing costs, so it has obvious economic benefits in mass production.

Carbon steel shows better wear resistance in high-frequency connection and disconnection situations. Couplers and plugs will be subject to repeated mechanical friction in daily operations, especially when the plug and coupler interface are frequently used. Wear resistance has become an important indicator in determining product life. Carbon steel can significantly improve its wear resistance and extend the service life of the product through surface hardening treatment.